NATIONAL COOLING TOWERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to NATIONAL COOLING TOWERS

Air Cooled Chilling Plants

Description / Specification of Air Cooled Chilling Plants

We are involved in offering a wide range of Air Cooled Chilling Plants to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Air Cooled Chilling Plants. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Chilling Plants

Description / Specification of Chilling Plants

We are involved in offering a wide range of Chilling Plants to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Chilling Plants. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

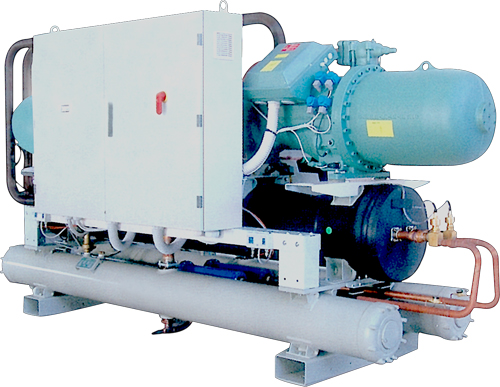

Water Cooled Chilling Plants

STANDARD FEATURES

● Compact & space saving.

● Easy to install & low maintenance cost.

● Low power consumption.

● Energy efficient air / water cooled compact chillers syitable for working in high ambient conditions.

● Manufactured & Design as per customer application.

● Control panel, visual function & fault indicator, Digital temperature controller.

● High / Low Pressure Guage and cutout with miniature circuit breaker system.

● Mimic display on panel.

● Low noise running and no pollution.

Brine Process Cooling System

National Cooling Towers make Brine Chillers for application demanding temperatures ranging from + 6 to C to -65 o C. Our Brine Chillers are unbelievably compact and modern. The Use of hermetically sealed compressor form Emerson, Danfoss and Copeland have made our chiller packages highly energy efficient. Further, the use of sophisticated two stage compressors with sub-cooler and related accessories have eased the achievement of temperatures as low as-65 o C. Our chiller packages can be integrated with insulated brine storage tank and re-circulating pump. These chillers find wide application in chemical process plants, anodizing / electroplating plants, laboratory applications, latex cooling etc.,

This system offers Water / Brine up to -30°C for process cooling purpose using Screw / Reciprocating type compressors. The capacity ranges from 3TR to 200TR and multiples. The company executed more than 1000 system for process cooling requirement.

Advantage Using National Cooling Tower makes Brine Chilling Plant

● Most economic solution

● Bulk holding tank with immersed cooling coil

● Upgraded technical solution: Shell & Tube type heat exchanging method

● Most advanced solution: Plate-type heat exchangers for evaporators and condensers (water-cooled)

● Compressors of the latest generation technology: scroll, semi-hermetic, hermetic, open, screw or

● Centrifugal type in systems compliant with Montreal Protocol

● Air-cooled or Water-cooled systems

● Heat pump systems

● Unique control, regulation & protection device with microprocessor based digital /analog systems

● Easy achievement of temperatures as low as -50 °C

● Can be provided with insulated brine storage tank & re-circulating pump

● Suitable for applications that demand temperatures ranging from +6°C to -50°

Water Process Cooling System

Description / Specification of Water Process Cooling System

We are involved in offering a wide range of Water Process Cooling System to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Water Process Cooling System. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Industrial Screw Chillers

National Cooling Towers make Brine Chillers for application demanding temperatures ranging from + 6 to C to -65 o C. Our Brine Chillers are unbelievably compact and modern. The Use of hermetically sealed compressor form Emerson, Danfoss and Copeland have made our chiller packages highly energy efficient. Further, the use of sophisticated two stage compressors with sub-cooler and related accessories have eased the achievement of temperatures as low as-65 o C. Our chiller packages can be integrated with insulated brine storage tank and re-circulating pump. These chillers find wide application in chemical process plants, anodizing / electroplating plants, laboratory applications, latex cooling etc.,

This system offers Water / Brine up to -30°C for process cooling purpose using Screw / Reciprocating type compressors. The capacity ranges from 3TR to 200TR and multiples. The company executed more than 1000 system for process cooling requirement.

Advantage Using National Cooling Tower makes Brine Chilling Plant

● Most economic solution

● Bulk holding tank with immersed cooling coil

● Upgraded technical solution: Shell & Tube type heat exchanging method

● Most advanced solution: Plate-type heat exchangers for evaporators and condensers (water-cooled)

● Compressors of the latest generation technology: scroll, semi-hermetic, hermetic, open, screw or

● Centrifugal type in systems compliant with Montreal Protocol

● Air-cooled or Water-cooled systems

● Heat pump systems

● Unique control, regulation & protection device with microprocessor based digital /analog systems

● Easy achievement of temperatures as low as -50 °C

● Can be provided with insulated brine storage tank & re-circulating pump

● Suitable for applications that demand temperatures ranging from +6°C to -50°

Multi Compressor Chillers

Multi Compressor Chiller contains number of compressors & variable speed drive for smooth functioning. It is used in various industries for chilling purposes like pharmaceutical, chemical, soap, food processing, beverage and many more. This Multi Compressor Chiller is manufactured by our experts by making use of the finest quality components and modern technology at our high-end production unit.

Scroll compressors perform at higher efficiency levels than reciprocating compressors. The compressors operate without cylinders, pistons or valves so it offers:

Inside the scroll compressor, two spiral-shaped members fit together forming crescent shaped gas pockets. One member remains stationary while the other orbits relative to first. This movement draws gas into the outer pocket and seals off an open passage. As the spiral movement continues, gas is forced toward the center of the scroll design, creating increasingly higher gas pressures.

With several pockets of gas simultaneously compressing, you receive a nearly continuous compression cycle. Gas discharges from a port at the center of the fixed scroll member. With both radial and axial compliance, the scroll members wear in rather than wear out.

Salient Features

● Robust construction

● High durability

● Superior performance

● Energy efficiency

● Low maintenance and high reliability

● Low noise and vibration levels

● Low space requirements

● Relatively low weight

Air Blast Coolers

Features

Chemical water treatment not required.

Cleaning and chlorinations not required.

Sealed system, no contamination of the water algie does not grow.

Water losses through evaporation is eliminated.

Low operating noise levels.

Low operating costs.

Minimal plan area.

Unsightly plumes of water vapour coming from your cooling equipment is stopped.

V-Type Coolers for reduced plan area.

Flatbed Coolers with horizontal or vertical airflow.

Box Type Fully packaged units incorporating pump, tank and starting equipment.

CONSTRUCTION OPTIONS

Tubes Copper : M.S. or stainless steel

Fins : Aluminium, copper, G.I. or stainless steel

Fan : Axial type at variable speeds to suit customer requirements

Casework : Galvanised steel, external painting, aluminium or stainless steel

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.